Featured Product Range

Eos. Our Modular Power Management System.

Hi-Fi and A/V cables employ either solid or stranded conductors depending on the application for which the cable was designed. These conductors are usually arranged in one of the configurations outlined below. Each configuration exhibits its own characteristics.

The bunch stranding method of construction is a relatively inexpensive way to produce a cable. Here the drawn strands are laid in the same direction, as a loose bunch. This method of construction is typically used in power cables, but can also be found in some Hi-Fi and A/V cables.

Since no particular attention is paid to the pattern in which individual strands are laid, the resulting cable’s cross-section is not perfectly circular, and individual strand lengths often vary. Cables produced this way therefore exhibit variations in characteristic impedance in the longitudinal direction, making them unsuitable for exacting audio applications.

The concentric lay cable comprises multiple layers of carefully laid strands (see diagram below). The number of strands per layer is limited, making it expensive to produce the perfectly circular multi-layered conductor required for high quality audio cables.

In order to build up a conductor where both flexibility and size are important, multiple stranded layers are laid in a twisted rope-lay pattern. These layers can consist of bunch stranded elements or concentric lay elements.

The concentric lay method produces the higher quality conductor. Concentric rope-lay stranded speaker cables have a larger cross-section than simple concentric stranded cables and, therefore, deeper bass.

The three construction methods outlined above produce cables with good flexibility, but which often suffer from non-circular cross-sections. Perfectly circular cables can be produced more easily using solid conductors. However, when a solid conductor’s cross-sectional area exceeds 1.5 sq mm, flexibility is lost, and bending readily causes the conductor to snap.

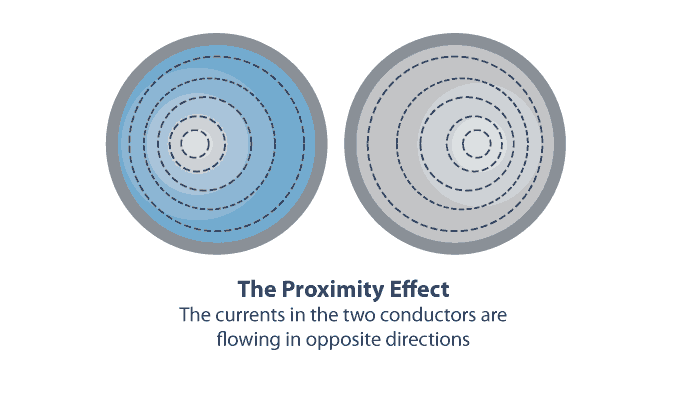

When cables are positioned side by side (in parallel pairs, or ‘figure of eight’ speaker cables), the going and return currents flowing in opposite directions repel each other because of the associated magnetic fields.

The current flow therefore becomes non-uniform across the cross-section of each conductor. This increases the conductor’s resistance. An alternative and more effective method of cable construction consists of twisting the two conductors together so that they are not parallel to each other and therefore do not suffer from the proximity effect.

Cable power loss is directly proportional to conductor resistance. Power loss relates to the amount of electrical energy converted into heat as the audio signal travels along the cable. The lower the resistance, the more efficient your system will be at converting electrical audio signals into sound.

High speaker cable resistance causes a decrease in damping factor. The coil in a loudspeaker generates its own back electromotive force which is ‘seen’ by the driving amplifier through the interconnecting cable’s resistance. In extreme cases this back EMF can damage the power amplifier.

When a cable transfers power from an amplifier to a speaker it does so by means of an A.C. current which flows within the going and return conductors. Each conductor ‘experiences’ a continuously reversing current flow.

It may be possible that cables using certain dielectrics or conductor materials can be directional as a result of the electron flow affecting the resistance of the cable. It’s certainly true to say that the sound from Atlas cables improves with use. It may be that the metal or more likely the dielectric adopts a position when charged and that as a result, current finds its route of least resistance. If a cable has been used in the same direction for a number of hours, the sound quality improves. If it’s then reversed, the sound reverts back to the original sound before use and eventually improves again with use in the reversed direction!

With the exception of some of our interconnect cables which are wired in a pseudo-balanced configuration (and are therefore directional by virtue of the way they are intended to be used), our cables when new from the carton should be considered non directional, but should not be reversed following use or burn in.

Cables are subject to vibrations or resonances just as any other hi-fi component. There are various resonance control devices and platforms available for equipment, but the vast majority of cable vendors completely ignore microphony in cables. Our speaker conductors are contained in a bed of cotton yarn inside the outer sheath in order to reduce the adverse effects of microphony.